Socket Screw Technical Information

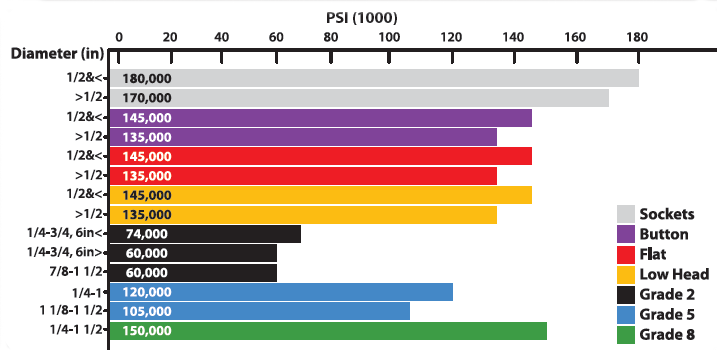

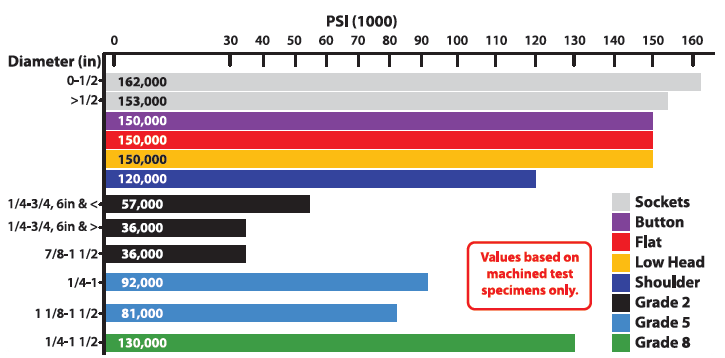

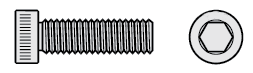

| Socket Head Cap Screws | Tensile Strength |

|

|

| Flat Socket Cap Screws | |

|

|

| Button Socket Cap Screws | Yield Strength |

|

|

| Socket Shoulder Screws | |

|

|

| Low Head Socket Cap Screws | Hardness HRC |

|

|

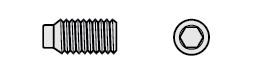

| Socket Set Screws | |

|

Applications

| Description | Use/Application | |

| Socket Screws | ||

| Socket Head Cap Screws | Used in fastening or clamping components together, die casting and machine assemblies among other uses. | |

| Flat Socket Cap Screws | Used in applications where counter sinking is desired. Used when a flush finish is required for either safety or appearance requirements. | |

| Button Socket Cap Screws | Used when appearance is a factor and clamping material is too thin for counter sink. Examples are end panels, display shelving and carts. | |

| Socket Shoulder Screws | Used in many tool and die applications as well as stationary guides, pulley shafts, moving shafts or pivots. | |

| Low Head Socket Cap Screws | Used in applications where not enough clearance is available for a standard socket head cap screw. | |

| Dowel Pins | Formed ends, controlled heat treat; close tolerances; standard for die work; also used as bearings, gages, precision parts, etc. | |

| Pipe Plugs |

3/4" taper (dry seal to help prevent leaks). 7/8" taper (flush seal to seat plug level with standard tapped hole). |

|

| Set Screws (Multiple Point Types) - Used to fasten shaft collars, gears and knobs on shafts or where frequent adjustments are involved. | ||

| Cup Point Set Screws | Used against hardened shafts or where frequent adjustments are needed and no locking point is required. | |

| Knurl Cup Set Screws | Similar to cup point but where vibration might be a problem. Knurls lock onto seating material and prevent screw from loosening. | |

| Cone Point Set Screws |  |

Used for permanent location of machine parts to shaft. Also used for pivots and fine adjustments. |

| Oval Point Set Screws | The oval point is used where frequent adjustments may be required. It may be used in applications where the point contacts the mating part at an angle. | |

| Half Dog Set Screws | Used for permanent location of one part to another. Point is often set into a drilled hole. May sometimes take the place of a dowel pin. | |

| Full Dog Set Screws |  |

Used for permanent location of one part to another. Point is often set into a drilled hole. May sometimes take the place of a dowel pin. |

| Flat Point Set Screws | Used when parts must frequently be reset. Causes very minor damage to part it seats against. | |

Critical Manufacturing Steps

Annealing

This process is important in preparing the raw material for cold heading as it changes the material structure into a finer crystalline state to allow for proper cold forming. The closely controlled heat and atmospheric conditions in the annealing process insure against brittle material events that can potentially lead to internal cracks within the finished component.

Forming

By utilizing rigid process controls out on the manufacturing floor during the heading process, our sockets exemplify superior fit, form and function. Tooling and dies are closely monitored for fatigue and wear at each forming station to help maintain sharp dimensions and tight tolerances.

Thread Forming

Thread rolling plates are meticulously monitored to produce consistent corners and angles in the thread profile, allowing for a uniform distribution of stress in the threaded area of each component.

Heat Treating

During heat treatment, the level of carbon in the atmosphere is closely monitored. The proper management of quenching, tempering and temperature throughout the heat treat cycle is imperative in producing components that meet the correct mechanical and chemical specifications.